|

|

|

This car was built for having fun! It was put together in about 3 months of long nights and weekends. I spent all of my time and money on the chassis and drivetrain (except for the motor). The car has run 10.55 @ 127.8 with a relatively stock motor on nitrous. The chassis and tinwork was done by Craig (Sudz) Freeman.

Rear end - Custom fabricated unequal length 4-link, coil over shocks, narrowed Ford 9" with 4.11 gears with a mini-spool, Moser alloy axels

I am currently waiting on a new motor from McQuillan Racing Engines (Leroy NY)

Quick specs on new motor.

Estimated Horsepower: 600+ on race gas, 550 on pump gas (lower boost)

383ci small block chevy. (.030 over 350 4-bolt block w/ steel stroker crank)

Dart Pro 1 Aluminum Cylinder Heads (230cc)

B&M Mega Blower

My first car was a "shove-ette" and was the inspiration for this project. I found that putting a V-8 in such a small car provided a terrific power to weight ratio. I put a 350 in my first Chevette and had a lot of fun with it, but it was kind of dangerous. The GM engineers did not design the car to go faster than 65mph. So I decided to get rid of it. Well, after a few years, I started to miss it. I remembered how much fun it was to drive. Somebody gave me a Chevette that had a blown motor, so I decided to re-create my first car (except a little safer).

When I first started on it, I was simply going to stuff a small block Chevy in the engine compartment as I had done on the first one. But I thought that I would reinforce the car a little bit by welding some round tube frame rails into the floor. Well, I discovered that the floor was rusty so I cut the floor pan out. A friend - Craig Freeman (Sudz) - was following my progress and he proceeded to talk me into building a full-boogie tube chassis for the car. I was reluctant at first because I had never attempted such task, but fortunately he had a lot of experience and was willing to help me.

It took about 3 months from the day I towed the car into the shop until I backed it out under its own power. We worked on it almost every night and weekend. We started by gutting the car and cutting the entire floor out of the car and removing all of the front clip and unibody structure. Pretty much the only thing that was left was the roof, rear quarter panels, and rocker panels. Sudz began building the chassis while I put an engine together, found a TH350 trans, a 9" Ford rear end out of an early Mustang. I had the rear end narrowed by Moser Engineering and started buying parts for the car (Coil overs, seats, fuel cell, brakes, gears, ignition, etc.). I fabricated all of the rear suspension from scratch. If I did it over again, I would probably buy all of the brackets for the 4-link and coil overs.

As the chassis came together, I started fabricating the smaller stuff like motor mounts, steering linkage, battery tray, drive-shaft hoop, radiator support, front sheet metal support, fuel cell mounts, etc. When the chassis was done, we sprayed it black.

Sudz then started on the tin-work. The entire interior was hand fabricated from .040" aluminum sheet. We did not have a shear, brake, or roll. The only tools Sudz used were tin snips, a makeshift brake made from angle iron, some files, a rubber hammer, and a lot of ingenuity and craftsmanship. The rear wheel wells had to be stretched a few inches to accommodate the large rear tires.

When the interior was done, the mechanical components were tended to next. Brakes, emergency brake, fuel system, electrical system were installed. The engine and transmission were hooked up and I took it for its first test drive about 3 months after starting the project. We did some rough body work and sprayed the car with gray primer to make it presentable. I then put it on the road and started driving it.

I took the car was to the Street Machine Nationals in Canfield Ohio in 1994 and won 1st place in the class "Best Car Under Construction". I have also taken it to several local shows and won in similar categories. It is a regular at some local "cruise ins"

I spent all of my money on the chassis and rear-end and just "threw" together a 350 for it. I figured that I could always build a motor for it later. I originally had the stock 28-spline axles narrowed and re-splined, but I discovered that they would not be acceptable for serious street duty when I twisted one of them about 45 degrees and broke the other completely. I got a set of high strength 31 spline alloy axles from Moser and haven't had any problems with them. I put a set of 4:11 Richmond gears in it with a mini-spool. After driving for a short time, I upgraded the stock TH350 transmission to a TCI Powerglide with a brake and a 10" converter. That made a big difference.

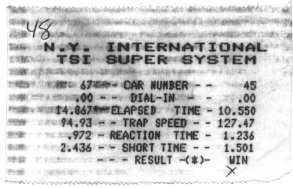

I live about 5 miles away from a 1/4 mile drag strip, so it didn't take me long to get the car down there. My first pass was about 13.5sec but I soon had it down to 12's and then into the 11's (with a relatively mild motor). I hooked up Nitrous Oxide and the car dipped to 10.55 at about 127mph. It also pulled the front tires off from the ground on two passes and carried them for about 20 feet. I calculated that the motor was only making about 300hp off the juice and about 410hp on it.

After driving the car for several years in primer, I decided that it was time to paint it. The motor was about hosed so I also decided to put a fresh one in before the paint job. I built a 406" with a stock bottom end, medium cam and some decent heads (2.02, angle plug, small chamger, GM castings).

To be continued ...